Model 28 TTY project...Part Three - the work continues... |

|

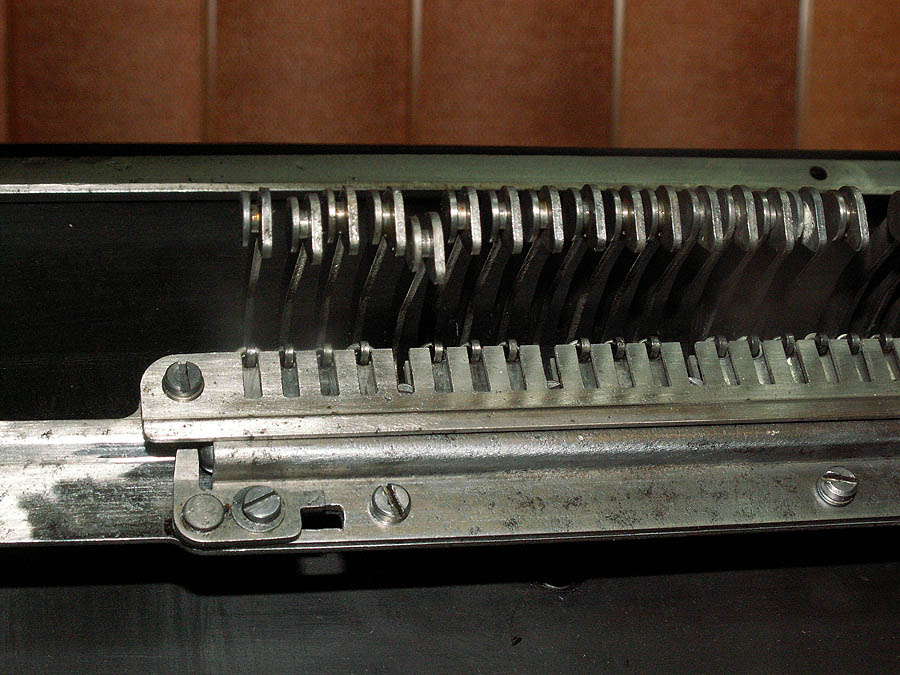

| After the keyboard frame comes the inter-lock ball mechanism. Each of the operational keys have a wedge that interfaces with the balls, where the chassis stand is tilted back so they don't fall off the tang. |

|

| The interlock ball track assembly has been swung up into position so that each of the wedges is between it's two balls in the track. |

|

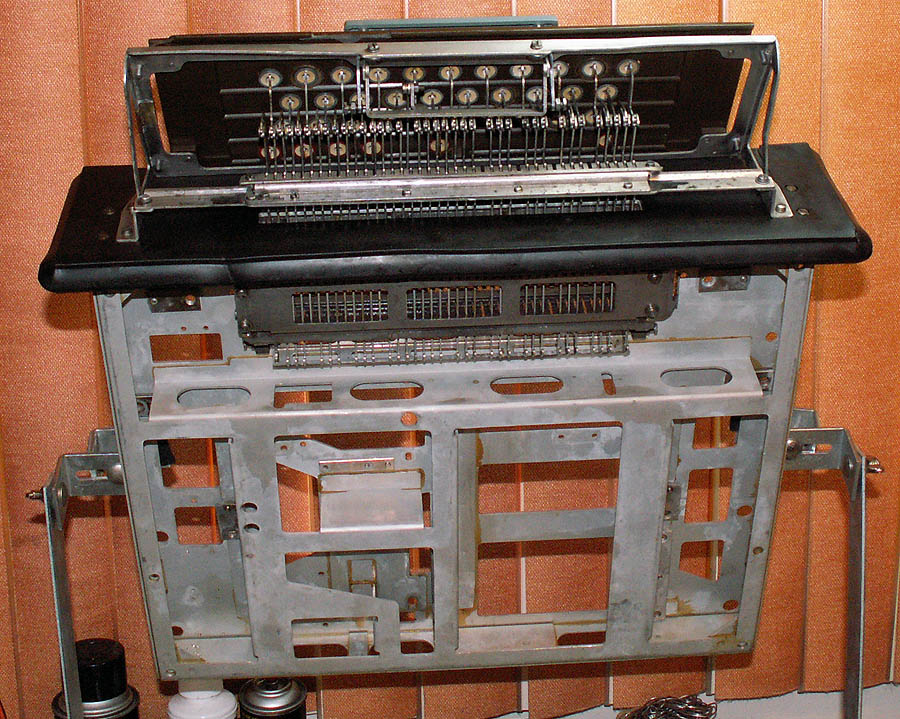

| Here the keytops have all been installed. Again - the chassis stand makes this job much easier - as one can see what they're doing without having to stand on their head. Problem discovered - either the plastic in the space bar has shrunken (most likely)- or the plastic in the keytop guide plate has - either way - the spacebar legs no longer pass through cleanly - and drag pretty bad. The Dremel will be used to clear some material in the guide plate - as there is nothing (practically speaking) that can be done with the space bar itself. Between an emergency service call early this morning - and church - that only leaves Sunday afternoon... which is slipping by fast... but still - it's (almost) looking like a teletype again... |

|

|

|

Speaking of coming along - what about Riceguy's TT-98? |

| Well - with the wiring issues finally put to rest (nothing like fresh by-pass caps.!)... the TT-98 is back doing it's thing. |

| And looking just as good! Well done Riceguy!... Motivation to move my project along - for sure!!!! |

|

|

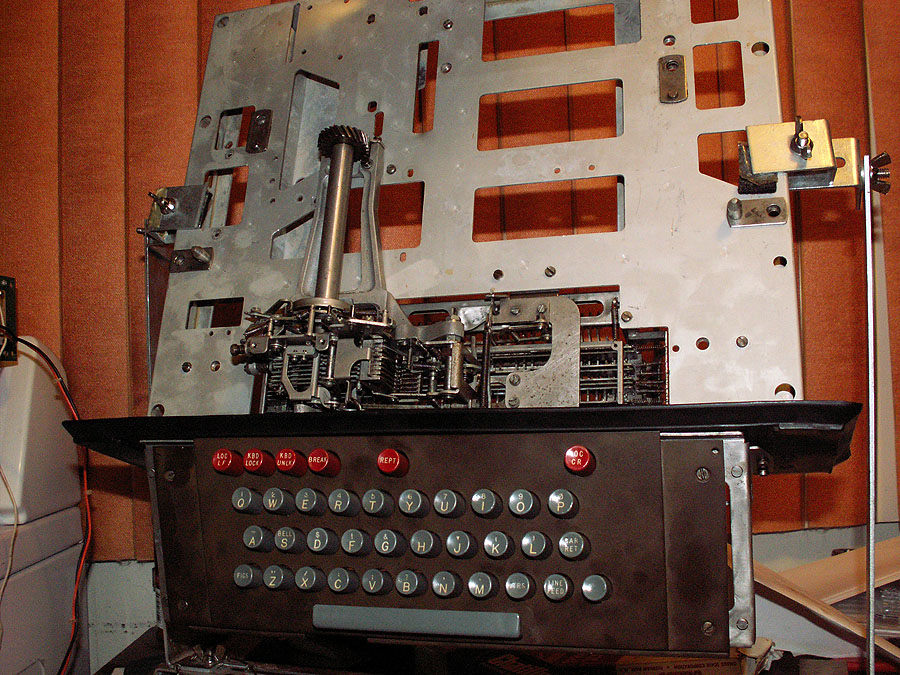

| Back to the 28. |

|

| More keyboard parts installed. And the first bit of trouble. There are obvious mis-alignments and bent parts in the code bail latch and anti-repeat assembly. Another bad sign is that when the code bar bail is "latched" back - the code bars aren't being pulled far enough to the left to allow the key-code levers to clear the code "teeth". A bit of a "tweak" on the code bar bail latch (O-249 p/n 151186) and it now pulls the code bars far enough (barely - any more and it fails to latch). Now the keys work as they should - but there's still a problem: when a key is pressed- the key bail rotates as it should and releases the code lever bail latch lever (O-131 p/n 151008) - which then drops down - and should push the code bar bail latch down so that the code bail swings to the right - setting the code into the code bars - and releasing the clutch. That never happens. First - the lever hits "bottom" on the code bail before it travels down far enough to cause the code bar bail latch to release. Even more troubling - is that even when extra clearance is provided to allow enough travel - the code lever bail latch lever doesn't have enough "ooomph" to press the code car bail latch lever far enough (some extra tension on the spring (O-132 p/n 70388) is enough - and everything fires. Problem with that, though - is that my spring gauge shows the spring in the code lever bail latch lever is correct (3 - 5 ounces - measures 4). So more investigation is needed to determine what issues there are - and what parts may be needed. This is a VERY old keyboard - (I'm not sure if it's a "Mk I"; but there are many parts differences between this and a Mk II). It's late - and this is going to have to be for another day... |

|

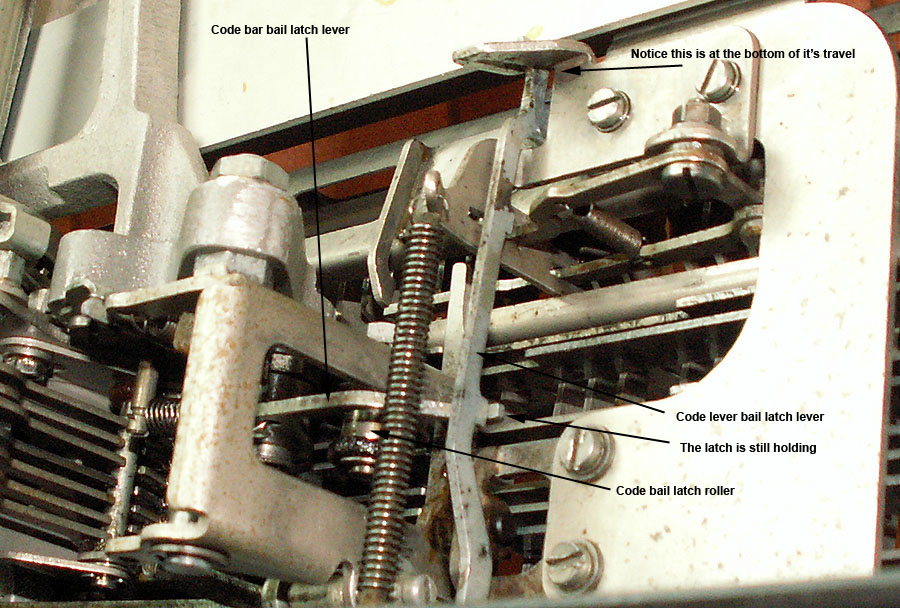

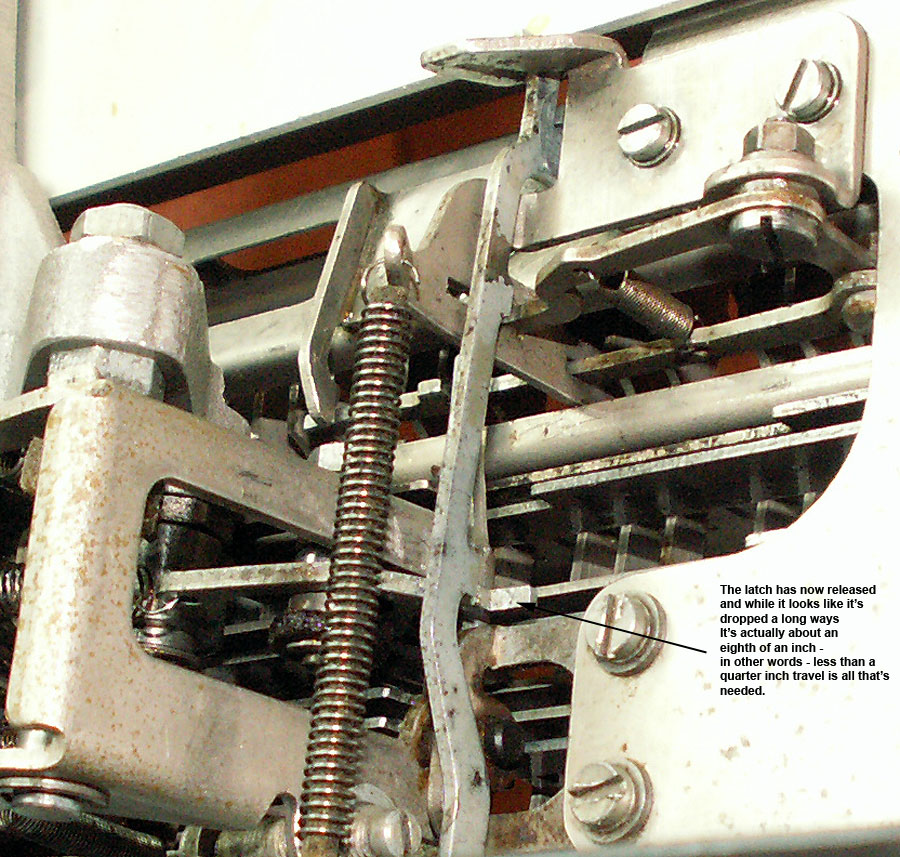

| Close up of the trouble area... |

|

| If'n it weren't broke - wouldn't be as much fun. |

|

Then again... if at first you don't succeed...

They say if you are stuck - take a break - then try again - and maybe things will be a bit clearer. That's the case here. Didn't have but about an hour this evening... however - that was enough. Already had identified the symptoms pretty well... Now to diagnose the cause(s). First - we knew that the code bail latch lever wasn't pushing down far enough. What if we "adjusted" it a bit (a couple of big wrenches applied ever so carefully) raising the far end a bit. Well now it travels far enough to push the code bar bail latch enough to unlatch the code bar bail. However - it still need some "help" - the spring just isn't enough on it's own. It doesn't take much - but some thing's still not right. Notice in the pictures above the code bail latch roller - and specifically the felt oil washer between the roller and the "C" clip. Turns out that sucker is as hard as a rock - and is (almost) preventing the roller from turning. Now teletype used as few ball and roller bearings as they could - but this is one place where they wanted very little friction - so the roller rides on a set of needle rollers. - Teeny-tiny ones to be sure - but they are there for a reason - and having a hard felt oil pad impeding the rotation isn't good. So out it all came - degreased and checked the rollers - very smooth -and turns effortlessly. Clean, oil and re-install the felt washer and the roller doesn't want to turn. So new felt pad is cut to size - oiled and installed. Now the roller turns effortlessly - and the spring is plenty to operate the latch on it's own. Adjusted the code bar bail latch itself to move the code bars left just a bit more - now the "code teeth" are centered over the key levers. But nothing is ever simple. Now - the code bar bail doesn't quite latch - fortunately there is an adjustment for that - and even with these adjustments the latch releases as it should. But up jumps another problem: Now when the keyboard shaft is operated pretty fast (well as fast as can be hand spun) - the key lever bail flips on over too far. Normally - the lower stop on the code lever bail latch lever prevents it from rotation too far forward - however - now the code lever bail latch lever is traveling too high - and the tang on the bail is sailing right past. Remember that "tweak" a bit earlier - turns out it was about a 1/32 of an inch too aggressive - and needed a bit of correction. Now the keyboard is operating as it should. Of course the real test will be "at speed" - but that'll have to wait until we get some more work done. Working well enough for now - if it turns out that it won't "hold" at speed - then fresh parts will be in order. But that's for another day. |

|

|

|

|

| Site contents copyright © 2008 Randy Guttery |

|

|